Tiscon ReadyBuild

Precise cut & bend rebars customised on state of the art machineryWhat does Tiscon ReadyBuild stand for?

Tiscon ReadyBuild is a downstream service brand which gives customised solutions for all your construction needs related to rebars. In line with the endeavour to come closer to the infrastructure industry, Tiscon ReadyBuild stands as an effort to bring hassle-free construction when it comes to rebar usage.

What is ReadyBuild?

Adding to the long list of innovations in products & services, the latest entrant from Tata Tiscon is Tiscon ReadyBuild.

Tiscon ReadyBuild, a rebar downstream service presently offers the Cut & Bend, Couplers and BBS Development Services that aims at providing customised rebar shapes of rebar needed at the construction sites.

Key Benefits of Tiscon Readybuild

Manage Space Effectively

On Time in Full Delivery (OTIF) of tailor-made rebars helps in managing space efficiently

Ensure Top Quality

High quality rebars are customised in the exact shape and size as per requirements

No wastage, No worries

Zero wastage on site eliminates disposal needs

Project Completion On Time

The time saved in the process of using customised rebars ensures that the projects are completed on time

Minimise Labour Involvement

Lowers labour involvement at site thereby reducing labour cost and manual errors

Safety

Laser cutting and bending work at sites provides greater safety to workers

Cut & Bend

What is Cut and Bend?

The cut and bend structures required in construction often use rebars of different shapes and sizes. Often cutting & bending of the rebars is done at the construction site by the unskilled labours. Since it is manually done by the labourers, there are high chances of inaccuracies & inefficiencies in the system.

There are many other challenges that are faced by different stakeholders during the construction process that includes timely availability of material, skilled labour shortages, wastages, scrap disposal etc.

Cut and bend service under Tiscon ReadyBuild aims at providing customised shapes of rebars needed at the construction sites. With ReadyBuild, the construction companies don’t need to worry about the availability of SKUs needed in the Cut and Bend structure. The ReadyBuild Centres customise the lengths of the rebars and bend them at required angles in accordance with the project’s blueprint. It can make the common shapes stirrups to complex helical shapes.

The cut & bend production processes at ReadyBuild Centres involve 3 world class fully-automated Italian make machines.

Shearline is a specialist cutting machine that cuts the rebar to required length with extreme precision. Robo Smart is a bending machine that gives rebar the required shape by bending rebars at required angles. It can bend rebars of all sizes ranging from 6mm-40mm.

Prima R is a specialist coil machine which is used to make stirrups of different shapes. It uses the coils of sizes 6mm-12mm.

Tiscon ReadyBuild provides the reliability of steel and supply, better site productivity due to reduced involvement of labour and reduced wastage. Our centre gives a ‘just-in-time’ delivery service that works like clockwork to meet a project’s ‘cut and bend’ needs in compliance with the client’s working schedule.

Couplers

What are Couplers?

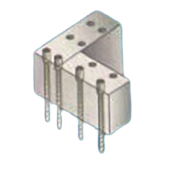

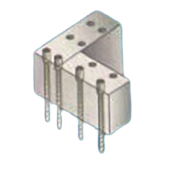

Couplers are hollow mechanical structures which are threaded inside and screwed on to two rebars, which are combined to form a mechanical joint. Tata Tiscon is the only Indian steel producer that manufactures its own line of mechanical couplers, which are to be used with Tata Tiscon rebars.

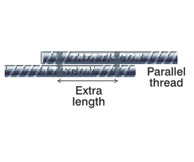

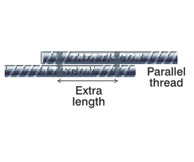

A coupler is used to reinforce bar joints between two rebars. The existing method to combine rebars is called ‘lapping’. This is a process where two rebars are laid parallel to each other over a certain length and then tied together using a binding wire.

This lapping process is extremely difficult, labour intensive and time consuming. Furthermore, it involves the usage of additional material like concrete, rebars and wires to increase the strength of the joints which leads to an escalation in costs.

In accordance with the IS 456 – 2000 code of practice, mechanical couplers can be used to combine two rebars. Tiscon ReadyBuild’s Couplers comply with En8D grade to ensure the chemical composition of all products match their predefined specifications. Our couplers are available in an SKU range from 16mm to 40mm, covering a wide range of customer needs, while ensuring structural integrity and savings in costs.

The benefits of using Tiscon ReadyBuild Couplers:

REDUCE REBAR USAGE

- Avoid lapping and optimize rebar usage

- Avoid labour efforts and costs for lapping and binding

REDUCE CONGESTION

- Allows optimum concrete binding and improves higher structural integrity

- Ideal steel ratio at structural member cross section

HIGHER STRUCTURAL INTEGRITY

- Rebar joints are less dependent on the concrete for load transfer

FASTER CONSTRUCTION

- Reduced handling and faster assembly ensures quicker installations

EASIER FUTURE INSTALLATIONS

- Can be installed as provisions for future installations

- Avoid the look of jutting out rebars and get a cleaner finish

REDUCE REBAR USAGE

- Avoid lapping and optimize rebar usage

- Avoid labour efforts and costs for lapping and binding

REDUCE CONGESTION

- Allows optimum concrete binding and improves higher structural integrity

- Ideal steel ratio at structural member cross section

HIGHER STRUCTURAL INTEGRITY

- Rebar joints are less dependent on the concrete for load transfer

FASTER CONSTRUCTION

- Reduced handling and faster assembly ensures quicker installations

EASIER FUTURE INSTALLATIONS

- Can be installed as provisions for future installations

- Avoid the look of jutting out rebars and get a cleaner finish